Guangzhou Hartek Technology Co., Ltd. Successfully Deploys Innovative Laboratory Extrusion System

November 28, 2025

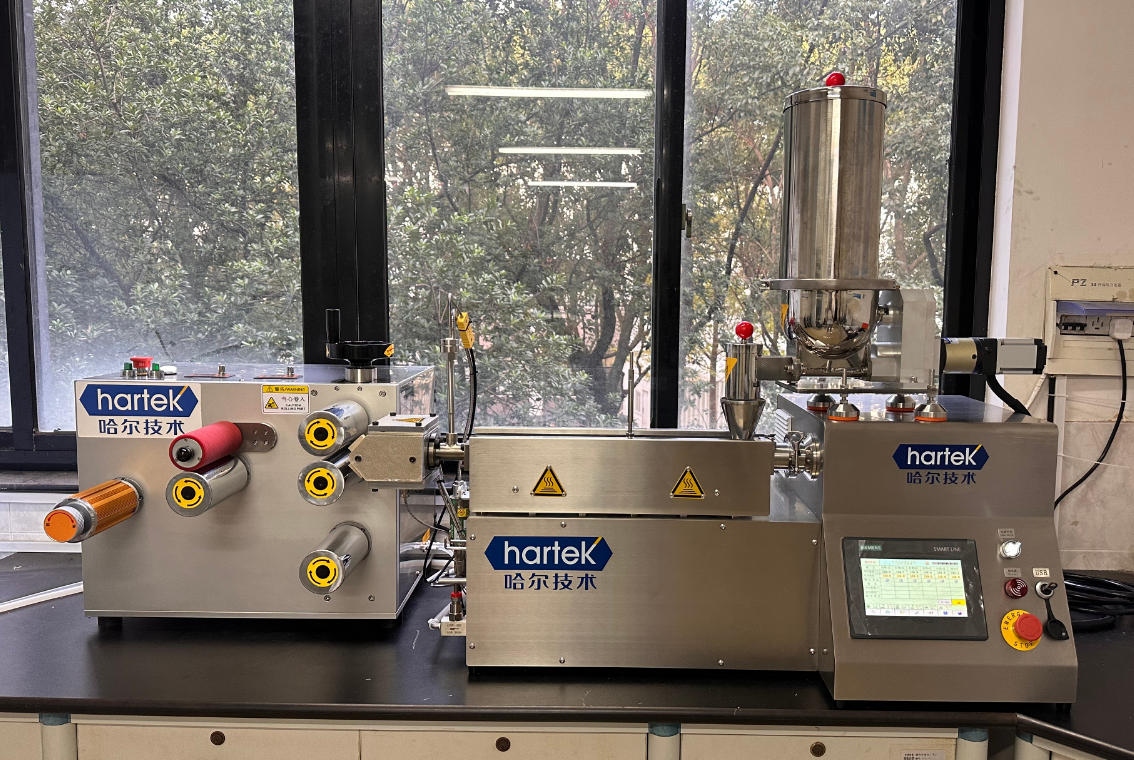

Guangzhou Hartek Technology Co., Ltd. (hereinafter "Hartek Technology") announced the successful delivery, installation, commissioning, and operator training of its Desktop Twin-Screw Sheet Extrusion Pilot Line for a client in Hangzhou. This compact, modular system is engineered to advance polymer research and development in space-constrained laboratory environments.

Space-Efficient Design

The desktop configuration minimizes floor space requirements, making it ideal for laboratories with limited room.

Modular Flexibility

Equipped with a high-performance parallel co-rotating twin-screw extrusion unit, the system supports customizable module combinations to accommodate diverse experimental needs.

Precision Temperature Control

Independent heating zones ensure temperature accuracy within ±1°C, guaranteeing process stability and product quality.

Integrated Production Workflow

The system consolidates melt filtration, static mixing, die assembly, three-roll calendering, and winding units into a seamless sheet production line.

· Biodegradable Material Validation

Enables feasibility studies for sheet forming of PLA, PBAT, PHA, and other biodegradable polymers.

· Natural Polymer Extrusion

Supports pilot-scale extrusion of starch-based or cellulose-based composites.

· Modified Sheet Development

Facilitates experiments with high-fill inorganic additives (e.g., calcium carbonate, talc) or recycled plastics.

· Functional Material Research

Suitable for producing antimicrobial, barrier, or conductive composite sheets.

· R&D Formulation Optimization

Aids universities, research institutes, and corporate labs in recipe screening and process refinement.

Hartek Technology specializes in designing and manufacturing miniature experimental plastic processing equipment. The company offers comprehensive technical consulting, turnkey solutions, and laboratory planning services. Its product portfolio includes:

· Mini extruders, cast film lines, blown film units, and sheet calenders

· Twin-screw extruders (including hot-melt and micro-counter-rotating variants)

· Three-roll calenders, internal mixers, two-roll mills, and 3D printing filament lines

· Multi-layer co-extrusion systems and defect-detection film lines

These systems are lauded for their versatile functionality, user-friendly operation, and scalability. They serve critical roles in formulation development, quality control, innovation research, and technical training for polymer (plastic/rubber) studies, industrial R&D, and academic programs.

Hartek Technology remains committed to its "Innovation-Driven, Quality-First" philosophy, partnering with clients to advance materials science and industrial progress.